∠ Tel:+86-29-86330856

∠ Mobile:+86-18609284085

2018-3-8

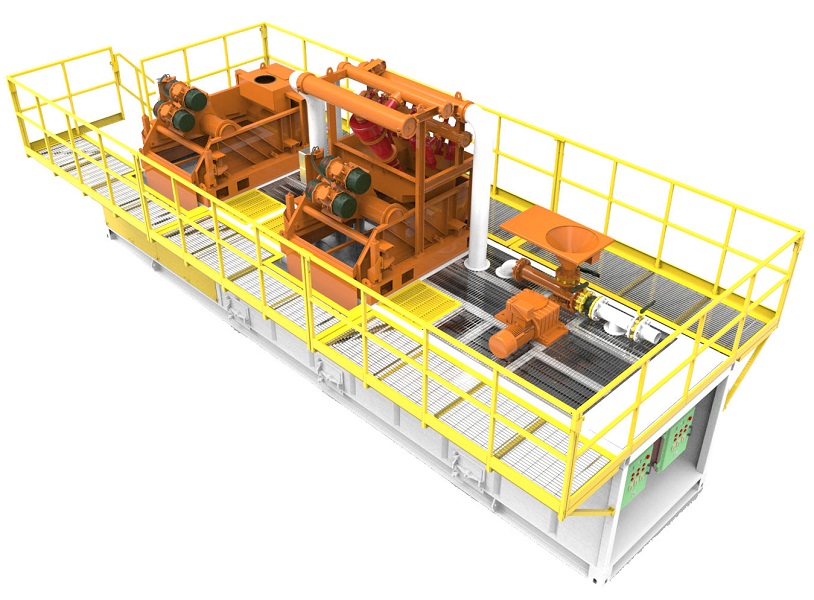

Mud recycling systems were once considered optional equipment. Environmental regulations continue to become more stringent to protect our fragile ecosystem.

Using mud recyclers is a valuable asset to drilling contractors, as well-conditioned drilling fluid can save resources, time and money by reducing the amount of water and chemicals needed by reusing your bentonite and water. This helps maintain borehole stability with consistent mud properties through the entire circulation of the fluid and you haul off mainly the drilled solids, not the entire mud returns, including the liquid.

Drillers considering a mud recycler often ask: “Where do I start?” There are factors to consider before purchasing (or renting) a mud recycler, and just like sizing the drill rig, sizing the recycler is equally important to your success. The following are some of the questions to ask yourself before making your purchase:

1. Type of drill rig will you be using?

2. Length of your average bore?

3. GPM of my mud pump or do I need a mud pump on the recycler?

4. Type and size of shakers on the unit?

5. Shaker screen sizes and availability, what is “mesh size”?

6. How do I know if the recycler is working?

7. Purpose of hydrocyclones, and how are they rated?

8. Do I need a trash pump?

9. Parts, service and warranty?

These factors are important to know so that you use a recycler that is sized to clean the mud and protect the components on the rig, pump and cleaner.

Drilling rigs are generally classified as “maxi,” “midsize” and “compact”. While you can put a maxi recycler with a compact rig, it would not be advisable to do the reverse. Lesson: size accordingly.

Generally, longer bore holes require a larger pit volume in order to properly process the drill solids before sending the fluid back down hole.

As a general rule, size the recycler cleaning capacity to one and a half to two times the pumping volume (max gpm) of the triplex pump. HDD drillers normally run thicker fluids due to the low vertical height and long horizontal lengths of their bores; thicker fluid makes it more difficult for the shakers and cones to process (separate) the solids from the liquids. This is largely due to the natural coating ability of bentonite — It wants to encapsulate the solids and “hold on” to them. By upsizing the recycler, the solid particles have a second or third opportunity to process through the mud recycler for removal before going back to the rig.

Example: If you are pumping 200 gpm, you would need a 350- to 400-gpm recycler.

Some mud recyclers provide an “onboard” mud pump that was sized specifically to the recycler. This enables the driller to use all available drill rig horsepower toward the rotation and push-pull of the drill pipe, thereby not “robbing” it for an onboard triplex pump.

-To be continued-